What is Ventilated Container – A Complete in Dept Guide

Introduction

In the dynamic world of global trade, transporting perishable goods is pivotal in determining supply chain efficiency. But, gone are the days when traditional shipping methods posed challenges for perishable items; ventilated containers present an innovative solution for the UAE’s logistics landscape.

Let’s see how these containers empower logistics professionals to uphold the integrity of goods during transit.

What is a Ventilated Container?

Definition and Purpose of Ventilated Container

Ventilated containers are specialized shipping containers designed with openings or perforations to control internal airflow. They help move perishable goods, like fruits, vegetables, flowers, and pharmaceuticals while maintaining optimal temperature and humidity levels.

Differentiating Ventilated Container from Other Container Types

Here are some key differences:

- Specific openings or perforations, common only to ventilated containers, facilitate controlled airflow and proper ventilation internally.

- These containers are purpose-built to transport perishable items in a protective environment that helps maintain product freshness and quality during transit.

- Some vented containers have optional refrigeration capabilities for precise temperature control.

- Ventilated containers offer some level of security, but less than their regular counterparts.

Six Key Features and Components of Ventilated Container

- Ventilation openings or perforations

- Temperature regulation

- Insulated walls and roofs

- Specialized flooring

- Humidity control

- Eco-friendly materials construction

The Benefits of Using a Ventilated Container

The key benefits of container ventilation include:

Improved Air Circulation for Perishable Goods

Ventilation openings create a well-ventilated environment for the cargo. As fresh air circulates throughout, it helps regulate temperature and humidity levels, preventing heat and moisture buildup.

Prevention of Condensation and Mold Growth

The controlled airflow and proper ventilation inside ventilated containers eliminate excess moisture that can cause condensation. By keeping a dry interior, these containers safeguard perishable goods from mold growth, which harms their quality and safety.

Enhanced Freshness and Quality of Cargo

By preventing temperature fluctuations and minimizing exposure to moisture, ventilated containers preserve the natural characteristics of fruits, vegetables, and flowers, extending their shelf life and reducing spoilage.

Suitable for Ventilated Storage and Transportation

Ventilated shipping containers incorporate openings that enable continuous airflow, ideal for storing perishable items in distribution centers or warehouses. Moreover, these containers facilitate the extended shelf life of perishable goods and safeguard product integrity.

IntroductionReduces Odor and Contamination Risks

The controlled airflow ensures efficient odors dispersal, preventing them from saturating other cargo or the container. Additionally, proper ventilation minimizes the buildup of excess moisture and mold, reducing potential contamination that could compromise cargo quality and safety.

Versatility for Different Types of Commodities

A ventilated shipping container is suitable for transporting various perishable goods, preserving their freshness and quality. It can also cater to non-perishable items.

Intermodal and Long-Distance Shipping Capability

These containers seamlessly integrate into various transportation modes, including ships, trucks, and trains. Their standardized sizes allow for easy interchangeability between different carriers, making intermodal transfers smooth and cost-effective.

Eco-Friendly and Sustainable Solution

Ventilated shipping containers reduce the need for energy-intensive refrigeration during transportation, minimizing carbon emissions. Some containers are also constructed using eco-friendly materials and are recyclable.

Compliance with Industry Standards

The design and manufacturing of ventilated shipping containers fulfill specific criteria, including proper ventilation, insulation, security features, and size specifications. Rigorous testing and certification processes also verify their suitability for hauling perishable or sensitive cargo.

Customizable Ventilation Options for Specific Cargo Requirements

Ventilated shipping container can feature adjustable vents or settings to accommodate diverse cargo requirements, ensuring that each shipment receives the ideal ventilation conditions for preserving freshness and quality.

What are the Different Dimensions of Ventilated Containers?

Overview of Standard Sizes: 20ft and 40ft Ventilated Container

Standard sizes for ventilated shipping containers typically include 20-foot and 40-foot-long containers, having similar widths and heights.

Internal and External Dimensions of Ventilated Container

External Dimensions of 20-Foot Ventilated Container

Length | Width | Height |

20 feet in length | 8 feet in width | 8.5 feet in height |

Internal Dimensions of 20-Foot Ventilated Container

Length | Width | Height |

19 feet 4 inches in length | 7 feet 8 inches in width | 7 feet 10 inches in height |

External Dimensions of 40-Foot Ventilated Container

Length | Width | Height |

40 feet in length | 8 feet in width | 8.5 feet in height |

Internal Dimensions of 40-Foot Ventilated Container

Length | Width | Height |

39 feet 5 inches in length | 7 feet 8 inches in width | 7 feet 10 inches in height |

Load Capacity and Weight Restrictions

- 20-Foot Ventilated Container:

- Load Capacity: Approximately 28,000 to 30,000 kilograms (61,729 to 66,139 pounds).

- 40-Foot Ventilated Container:

- Load Capacity: Approximately 26,000 to 28,000 kilograms (57,320 to 61,729 pounds).

Get In Touch

Characteristics of Ventilated Container

Unique Design Features and Construction of Ventilated Container

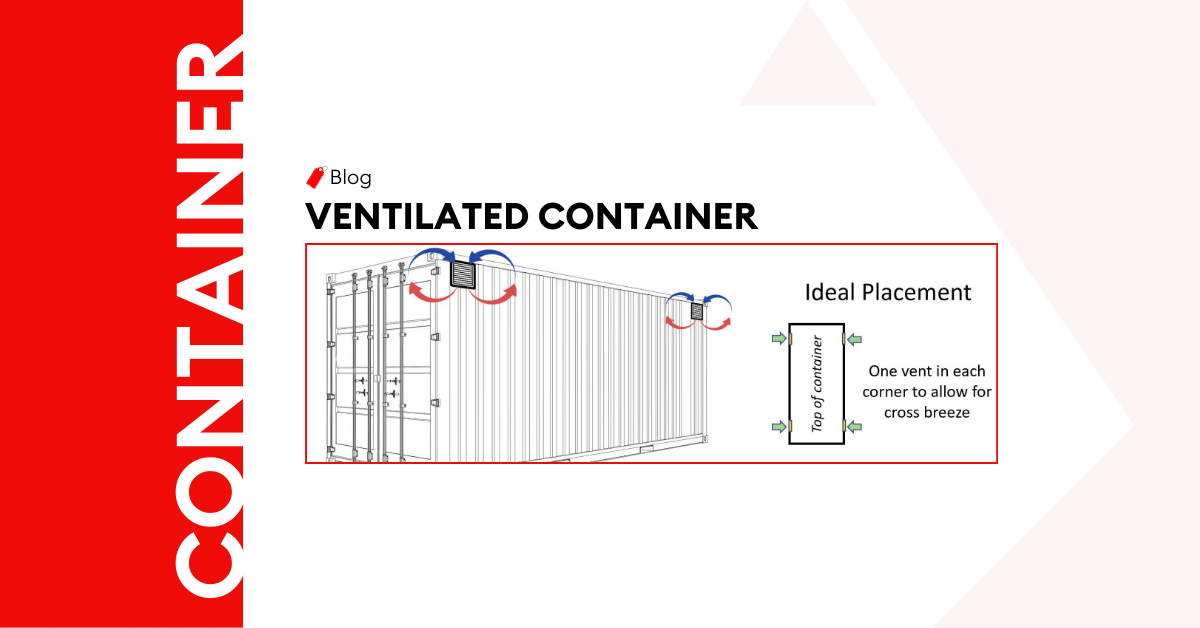

- Ventilation openings or perforations in the walls, roof, and/or flooring for controlled airflow.

- Insulated walls and roofs to maintain a stable internal temperature.

- Flooring design prevents condensation and ensures proper drainage.

- Some ventilated containers have optional refrigeration units, known as “Reefer” containers.

- Standard corner castings and twist-lock fittings, enabling easy handling and secure stacking.

- Standard locking mechanisms and security features protect the cargo from theft and tampering.

- Eco-friendly construction, contributing to sustainable and environmentally friendly operations.

Flooring and Load Securing Mechanisms

The flooring in ventilated shipping containers is specially designed to prevent condensation and ensure proper drainage, reducing the risk of cargo damage caused by moisture. Load securing mechanisms, such as D-rings or lashing bars, along the container’s interior enable cargo to be securely fastened and prevent shifting or damage during transportation.

Structural Strength and Durability

Ventilated shipping containers are engineered with robust steel to endure rough handling during loading and unloading, and stacking during intermodal transfers. Reinforced corners and double doors with sturdy seals enhance security and protect the cargo from external elements.

The Most Common Applications of Ventilated Containers

Overview of Industries and Cargo Types That Utilize Ventilated Containers

Ventilated containers find extensive use in agriculture and pharmaceutical industries that require transporting perishable and sensitive cargo. Floral, cosmetics, electronics, and textile products also benefit from controlled airflow and temperature regulation.

8 Examples of Specific Goods Transported Using Ventilated Containers

- Fresh fruits and vegetables

- Cut flowers and plants

- Temperature-sensitive medicines, vaccines, and medical supplies

- Fish, shrimp, lobster, and other seafood products

- Dairy products, such as milk, cheese, butter, and yogurt

- Beef, chicken, pork, and other meats

- Natural cosmetic products

- Sensitive electronic components and devices

How Al Sharqi Can Help with Ventilated Container Shipping

At Al Sharqi, our expertise in handling ventilated containers and specialized cargo enables us to provide secure and efficient transportation for your perishable goods. Safety is our priority, and our operations strictly comply with safety regulations and best practices to safeguard your valuable cargo throughout the shipping journey.

Our dedicated team crafts tailored logistics solutions for your unique ventilated container requirements, ensuring your goods arrive in prime condition. Partner with us at Al Sharqi for reliable and specialized shipping experience.

Conclusion

As shipping experts, understanding and using storage container with ventilation can unlock vast opportunities for logistics efficiency and sustainability in the UAE. From agriculture and pharmaceuticals to electronics and textiles, numerous industries can benefit from the customized solutions available. By incorporating ventilated containers into supply chain management, your business can enjoy seamless tracking, compliance with safety regulations, and enhanced cargo protection.

FAQs

Our experience in the field and our global network

A ventilated container is a unique shipping container designed with openings or perforations to allow controlled airflow throughout the cargo.

To ventilate a sea container, check for obstructions in pre-installed ventilation openings or perforations, position the cargo with adequate space around these openings for proper airflow, or consider using ventilation devices like fans or vents.

Ensure the existing ventilation openings are clear, elevate the container with wooden blocks or pallets, install ventilation fans, arrange the stored items with gaps between them, and regularly monitor the temperature and humidity levels.

Firstly, inspect it for leaks. Then, seal any gaps, holes, or openings with necessary sealants, place moisture absorbers (desiccant packs or silica gel) within the container, use pallets or raised platforms to elevate the cargo off the floor, and ensure adequate internal ventilation.

Shipping ventilation refers to the controlled flow of air within a shipping container in transit to maintain optimal conditions for the transported cargo.

Related Articles

Who Is Responsible for Demurrage Charges?

When it comes to shipping, people dealing in the trade at times may get charged with unexpected bill

What Is the Difference Between Detention and Demurrage?

Every step in the logistics operations is carried out according to proper agreements and contracts.

The Ultimate Guide to Dry Container {Types, Dimensions & Specifications}

Introduction In the vast ocean of international trade, about 90 percent of cargo transport relies on

Post a comment

You must be logged in to post a comment.