Tank Container & ISO Tank Container – The Ultimate Guide

Introduction to Tank Container & ISO Tank Container

In the thriving UAE shipping industry, tank containers and ISO containers facilitate the safe carriage of liquids, gases, and solids. So, they are vital across sectors like chemicals, oil and gas, and food and beverage.

Today, global businesses seek secure and cost-effective logistics solutions. Tank containers provide a way to achieve this goal. How? We provide all the details in this article.

What is a Tank Container?

Definition and Purpose of Tank Containers

Tank containers are specialized transport containers designed to safely and efficiently transport liquids, gases, and even solids. Their unique construction ensures they withstand the rigorous demands of intermodal transportation between ships, trucks, and trains.

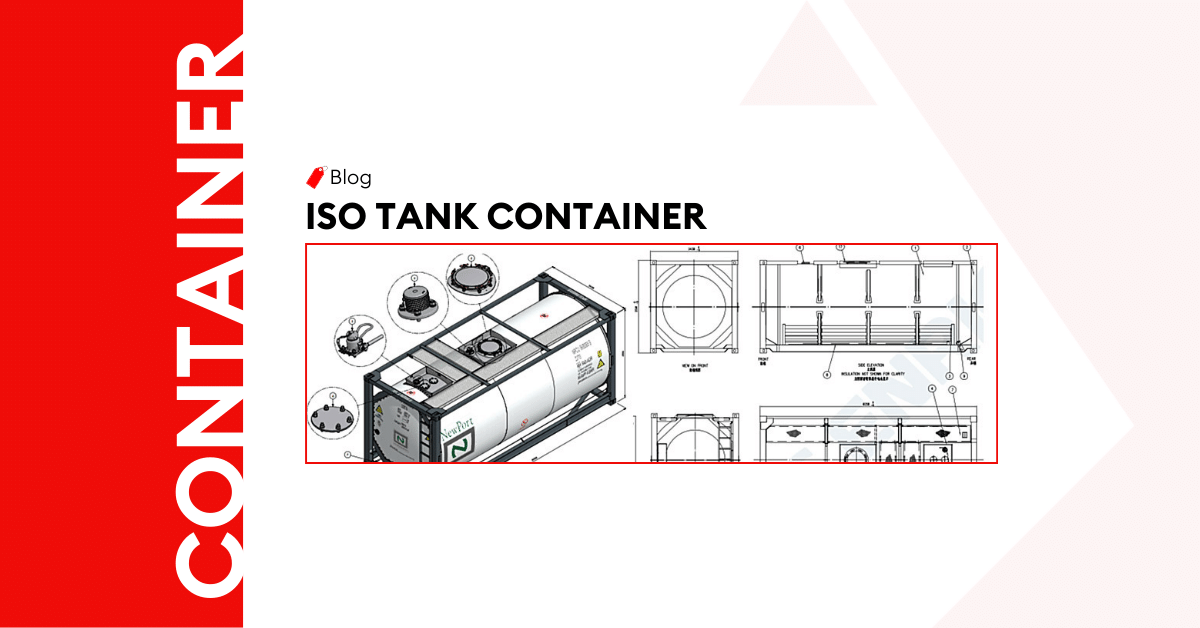

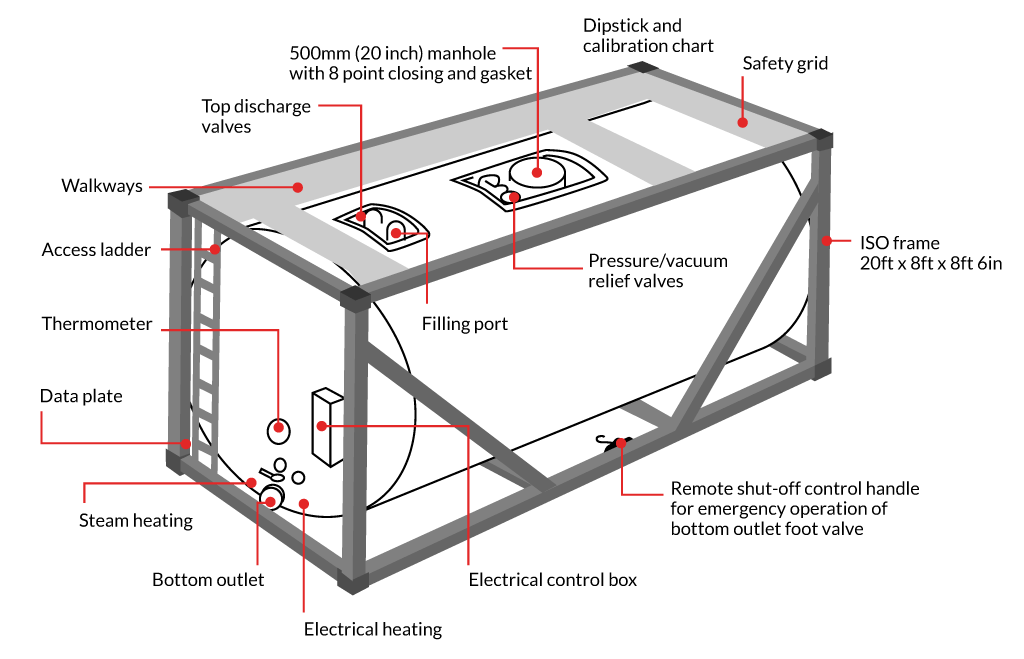

Key Components and Features of Tank Containers

- The tank shell, typically made of stainless steel or carbon steel.

- A robust steel frame that supports the tank shell, and corner castings for easy lifting and secure stacking of containers during transportation or storage.

- Manholes on top of the container allow for easy access to the tank interior for inspection, cleaning, and maintenance purposes.

Regulations and Safety Standards for Tank Containers

- International Maritime Organization (IMO) Regulations, such as the International Maritime Dangerous Goods (IMDG) Code, guide the safe movement of hazardous materials through proper labeling, packaging, and handling.

- Tank container certification by the International Organization for Standardization (ISO) deals with structural integrity, leak prevention, pressure testing, and compatibility with different modes of transport.

- Safety equipment and procedures require tank containers to have pressure relief devices, emergency shut-off valves, overfill protection systems, adequate ventilation, grounding, electrical safety measures, and strict protocols to prevent accidents or spillages.

Overview of Different Types of Tank Containers

Tank containers cater to the transport of various types of goods. However, these containers vary according to their applications. Examples are food-grade tanks, storehouse tanks, fuel tanks, lined tanks, heated tanks, reefer tanks, and SWAP-body tanks.

Specific Applications and Use Cases for Each Type

- Lined: to carry acids, solvents, fertilizers

- Fuel: for transporting gases

- Food-Grade: food items, edible oils, juices, and dairy products

- SWAP body: for extremely lightweight goods

- Storehouse: to ship grains and materials in powdered form

Benefits of Using Tank Containers

Enhanced Safety and Security

A secure environment for transporting hazardous materials, minimizing the risk of accidents, spills, or contamination. Also, protection against external elements and reduces the chances of tampering or unauthorized access.

Efficient Transport and Handling

Standardized dimensions which produce reduced handling and transfer time and ensure timely delivery of goods. Also, protection against temperature fluctuations and contamination when dealing with sensitive products.

Cost Savings and Versatility

The ISO liquid containers are versatile transport of various commodities such as chemicals, fuels, food-grade liquids, and pharmaceuticals. Plus, less intermediate packaging (drums, barrels) and better intermodal compatibility reduce handling and packaging costs.

Compatibility with Intermodal Transport

The intermodal tank types incorporate fittings that make them compatible with multiple means of cargo transportation, such as ships, trucks, and railcars.

How to Choose the Right Tank Container?

Understanding Cargo Requirements and Specifications

Specialized cargo considerations will be necessary for hazardous materials or food items to comply with international regulations and specific handling and storage guidelines. There are different ISO tank sizes and dimensions, which impact alignment with the transport vessel.

Considering Compatibility and Regulatory Compliance

Intermodal compatibility indicates tank container is compatible with the modes of transportation you plan to use. Also, the right tank container must follow applicable IMO, ISO, and Emirate standards.

Assessing Capacity, Dimensions, and Weight Restrictions

Capacity, measured in liters or cubic meters, determines the volume of goods a container can transport, while standard dimensions are 20 ft ISO tank container and 40-foot container.

Weight restrictions consider tare and gross weight limits for safe transport, while payload limitations refer to recommended maximum cargo weight. Assessing these factors ensures optimal space usage and less overloading or underutilization.

Evaluating Maintenance and Service Support

Good tank containers come with the availability of maintenance and service support. So, there must be easy access to repair services, spare parts, and technical assistance when needed.

Types of Tank Containers

Open Top Container

An Open Top tank shipping container is a specialized freight container used for transporting goods that usually exceed the container dimensions. Unlike typical containers with solid roofs, this container lacks a solid roof, making it suitable for oversized or bulky items that cannot fit within standard confines.

The absence of a fixed roof allows for easy loading and unloading of cargo from the top, often through removable or tarpaulin-covered openings. Reinforced corner castings facilitate secure stacking and stability during transportation.

Hardtop Conatiner

A Hard Top shipping container handles oversized or heavy cargo that requires top-loading capabilities while still providing robust protection. It features a solid steel yet removable roof to easily load and unload goods from the top, particularly for large machinery, industrial equipment, or bulky goods that cannot fit through standard container tanks doors.

The container’s durable steel construction ensures excellent structural integrity, while tie-down points or lashing bars help secure the cargo during transit.

Platform Container

A Platform shipping container consists of a flat, open, and robust steel base with fixed or collapsible end walls, offering a flexible loading platform for various cargo types. The absence of side walls and roofs allows for easy loading and unloading from any direction, making it ideal for goods with irregular shapes or sizes, such as machinery, vehicles, large pipes, or timber. Interior lashing points on the base and sides help secure cargo during transportation.

Dry Container

A Dry or Dry-Cargo container is the most widely used shipping container type in general goods freight. It has a standardized, rectangular metal box with solid walls, a floor, and double doors at one end. Dry containers offer convenience and efficiency in loading, unloading, and stacking.

Plus, the standardized dimensions enable seamless intermodal transport across ships, trucks, and trains, streamlining the logistics process. Their versatility of Dry Cargo containers makes them ideal for transporting electronics, clothing, furniture, and other consumer and industrial products.

Flat Rack Container

A Flat Rack shipping container also accommodates oversized or irregularly shaped goods that cannot fit into regular containers. A flat, open platform design with collapsible or fixed-end walls offers flexibility in loading and unloading cargo from the sides or the top. Additionally, no side walls allow easy access to the cargo, making it suitable for heavy machinery, vehicles, industrial equipment, pipes, and large project cargo. Flat Rack containers also feature robust corner reinforcements and lashing points to secure the cargo during transportation.

Insulated Shipping Container

An Insulated ISO tank storage maintains temperature-controlled conditions for sensitive goods during transportation. It features an insulating layer, typically polyurethane, aluminum sheets, or foam, for internal temperature regulation and safeguarding the cargo from extreme temperatures.

It’s suitable for perishable goods (food items, pharmaceuticals, chemicals, and electronics) which require specific temperature ranges to preserve their quality and integrity. The insulation prevents temperature fluctuations, reducing the risk of spoilage, degradation, or damage.

Intermediate Bulk Container

An Intermediate Bulk shipping container, or IBC, transports and stores bulk quantities of liquids, grains, or powders. It typically features a large, rectangular, or cubic shape, with a capacity ranging from 275 to 330 gallons (1000 to 1250 liters).

Generally, the IBC consists of a robust inner container made of plastic, stainless steel, or composite materials, enclosed within a protective outer cage or frame. Its design enables easy handling with forklifts or pallet jacks, and it can be stacked to optimize storage and transportation space when empty.

Pallet wide Container

A Pallet Wide shipping container features a special design that maximizes the storage capacity of standard pallets while ensuring efficient and safe transportation.

Unlike traditional containers, this container type is wider, allowing it to accommodate two rows of standard pallets side by side. So, the container can hold more cargo in a single shipment. This feature is valuable for retail, manufacturing, and distribution industries.

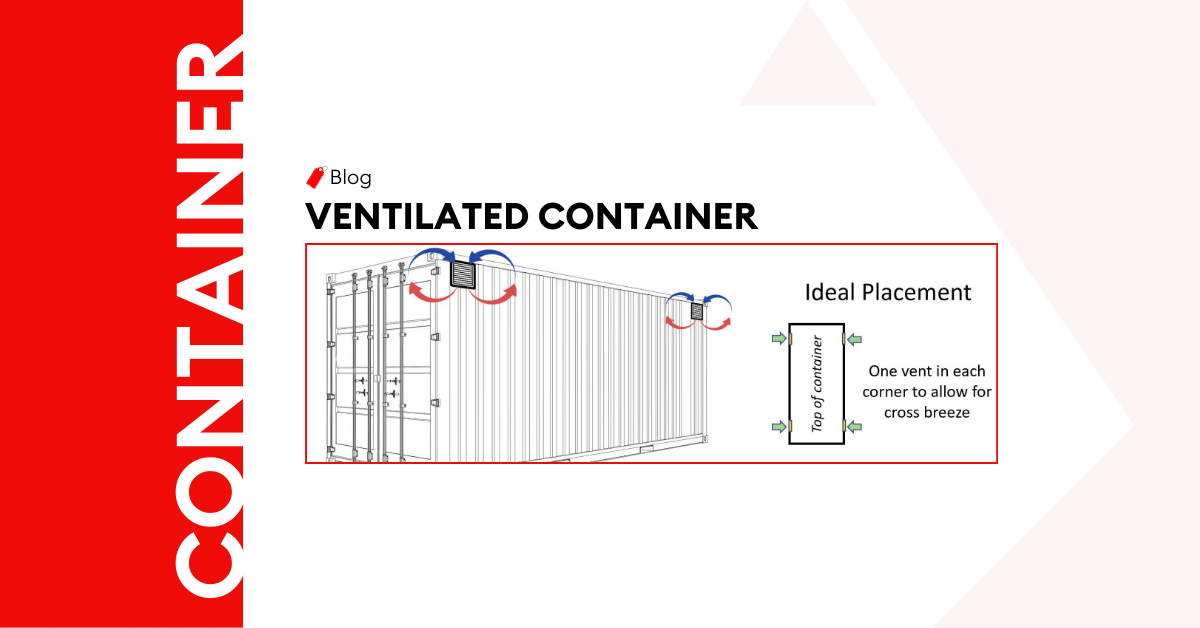

Ventilated Container

A Ventilated shipping container facilitates improved air circulation and ventilation when transporting certain goods. Typically, it includes additional openings, vents, or perforations in the walls and doors to enable fresh air flow hroughout the container.

Examples of cargo that may benefit from Ventilated containers include agricultural products like fruits, vegetables, or flowers that require proper ventilation to prevent moisture buildup, condensation, or odors. Essentially, the ventilation design helps maintain optimal temperature and humidity levels, reducing the risk of spoilage, mold growth, or deterioration of the cargo.

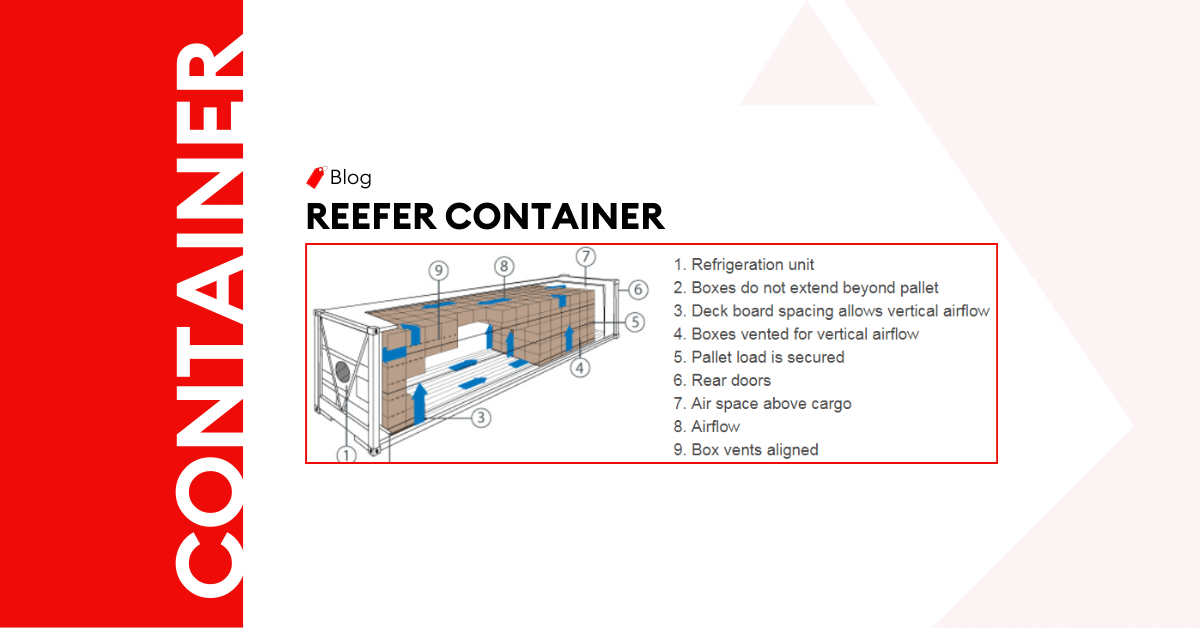

Reefer Container

A Reefer shipping container, or refrigerated container, transports temperature-sensitive goods at controlled and consistent temperatures. Built-in refrigeration or heating systems enable efficient temperature regulation to maintain the desired temperature range throughout the shipping journey.

Reefer containers are essential for transporting perishable items such as fruits, vegetables, meat, dairy products, pharmaceuticals, and other temperature-sensitive goods.

The container’s temperature can be set to a specific range, ensuring the cargo remains fresh and in optimal condition during transit.

Get In Touch

ISO Tank Containers: An In-Depth Look

What is an ISO Tank?

ISO tankers, also known as intermodal tank containers, are versatile vessels for moving commodities via various modes of transport.

From chemicals to food-grade liquids, ISO tank containers have become vital in seamless intermodal transportation while adhering to international regulations and ensuring cargo integrity.

Importance of ISO Certification for Tank Containers

ISO certification indicates that tank containers comply with internationally recognized standards of the International Organization for Standardization (ISO). These standards encompass design, manufacturing, testing, and safety requirements.

It also signifies that ISO container tank has undergone rigorous inspections, testing, and quality control procedures, and are more likely to be reliable over long periods. And, it ensures adherence to structural integrity and leak prevention, which minimize safety hazards and safeguard lives, property, and the environment.

Common Types and Variations of ISO Tank Containers

- Rubber-lined ISO tank container

- T1 ISO

- T4 ISO

- T11 ISO

- T14 ISO

- T50 ISO

- T75 ISO

Dimensions and ISO Tank Specifications

The following are some of the standard ISO tank weight measurements:

- Capacity – varies between 21,000, 24,000, 25,000, and 26,000 liters

- Gross weight – 36,000 kg

- Tare weight – 3,650 kg (21,000L), 3,900 kg (24,000L), 3,730 kg (25,000L), and 4,060 kg (26,000L)

- Payload – 32,350 kg (21,000L), 32,100 kg (24,000L), 32,270 kg (25,000L), and 31,940 kg (26,000L)

Average Prices and Market Factors for ISO Tank Containers

The following factors affect container pricing

- Container demand and supply.

- Material and construction costs, including fluctuations and construction methods.

- Currency exchange rates across multiple countries.

- Container age and condition at the time of purchase.

- Additional features and customizations, including specialized linings, insulation, heating systems, or safety enhancements.

Uses and Applications of ISO Tank Containers

Overview of Various Industries Utilizing ISO Tank Containers

- Chemical: For the transportation of acids, solvents, petrochemicals, and specialty chemicals.

- Oil and gas: For petroleum products, liquefied gases, lubricants, and other related materials.

- Food and beverage: For moving perishable food items, frozen foods, and dairy products.

- Pharmaceutical and healthcare: For transporting pharmaceuticals, active ingredients, and other healthcare materials that require secure, temperature-controlled transport.

- Agriculture: For transporting liquid fertilizers, agricultural chemicals, seeds, grains, and other agricultural products.

Advantages for International Shipping and Trade

- Versatile and intermodal shipping of goods with multiple modes of transport, including ships, trucks, and railways.

- Streamlined operations and reduced complexities in loading, unloading, and handling.

- Secure and safe transport to prevent damage, spills, accidents, and contamination.

- Cost-effective logistics by combining bulk quantities of goods into one shipment.

- Reduced packaging and handling by eliminating the need for intermediate packaging, such as drums or barrels, for liquids, gases, or solids.

Exploring ISO Storage Tanks

Understanding ISO Storage Tanks and Their Purpose

ISO storage tanks have the stamp of approval from the ISO concerning consistent quality and reliability, which makes them suitable for intermodal transport.

Differentiating ISO Storage Tanks from Tank Containers

liquids or gases. Their large size and permanent placement make them unsuitable for frequent movement or transportation.

ISO tank containers, on the other hand, are portable tanks for carrying liquids, gases, or solids. ISO tank containers have standardized dimensions and fittings, allowing them to be seamlessly loaded, unloaded, stacked, and transported using standard container-handling equipment.

Key Considerations for ISO Tank Usage

When deciding on ISO tank truck, consider the following factors:

- Are the tank capacity and dimensions sufficient?

Assess the required volume of the stored substance, space restrictions, access for loading and unloading, and future expansion needs.

- What are the regulatory standards to comply with?

Ensure compliance with applicable regulations, standards, and permits when using ISO storage tanks, and check the local and international requirements affecting tank design, installation, operation, and maintenance.

- What are the safety and security measures in place?

Implement adequate safety and security measures to protect the ISO tanks and the stored substances, including proper grounding, ventilation, fire protection systems, and access control.

What is the Capacity of an ISO Tank Container?

Factors Affecting ISO Tankers’ Container Capacity

ISO tank dimensions and sizes: Variations in length, width, and height can exist, so these dimensions affect the possible capacity for cargo storage.

Type of Cargo: Higher-density cargo will occupy less tank volume, but less-dense cargo may occupy more volume and reduce the overall capacity.

Regulatory Requirements: Such as weight limits, safety regulations, and hazardous material classification which impact the usable capacity.

Internal Tank Design: The tank shape and the positioning of valves and fittings within it affect the usable volume for cargo storage.

Calculating and Understanding the Capacity Limitations

- Determine the nominal capacity/maximum volume, typically expressed in liters or cubic meters, that represents the absolute volume the tank can hold.

- Consider the recommended filling ratio – the percentage of the maximum volume that can contain the transported substance.

- Consider regulatory requirements specific to the UAE regarding maximum weight limits.

- Seek professional guidance from logistics experts who can provide accurate guidance on container tank usage and ensure regulatory compliance.

How Al Sharqi Can Help with Tank Container Shipping

With over 30 years of experience, Al Sharqi is your go-to logistics partner. We specialize in providing flexible and end-to-end logistics solutions in tank container and ISO container tanks services.

Our global network of partners gives us extensive geographic coverage when moving goods over short and long distances. Plus, up-to-date software integration in our transport services enables real-time tracking and monitoring. If you have particular tank shipping requirements, we get you the services you need. So, contact Al Sharqi today for top-level tank container logistics.

Conclusion

Tank containers and ISO containers are revolutionary container solutions in the global supply chain. Their features ensure goods remain safe while in transit. These containers also aid the use of intermodal transport.

Need secure, cost-effective transport for liquid, solid, and bulk commodities? Find a logistics partner that offers the right tank container services.

FAQs

Our experience in the field and our global network

A tank container transports liquids, gases, or solids while an ISO tank container adheres to International Organization for Standardization (ISO) dimensions for intermodal compatibility.

Tank containers provide standardized dimensions, intermodal compatibility, and safety features that enable cost-effective transport of various commodities, reduce packaging waste, and facilitate global trade connectivity.

Consider factors such as cargo type, volume requirements, compatibility with multiple transport modes, regulatory compliance, safety features, and cost-effectiveness. Also, conduct thorough research, assess your specific shipping requirements, and consult third-party logistics experts.

O certification is a globally recognized accreditation that confirms a tank container complies with established ISO specifications on quality, safety, and environmental standards.

ISO tank containers come in standard, lined, and refrigerated tanks. Standard tanks are 20′ ISO tank, while lined and refrigerated tanks can vary in length from 20 to 40 feet. Capacities range from around 14,000 to 27,000 liters.

Related Articles

The Ultimate Guide to Dry Container {Types, Dimensions & Specifications}

Introduction In the vast ocean of international trade, about 90 percent of cargo transport relies on

What is Ventilated Container – A Complete in Dept Guide

Introduction In the dynamic world of global trade, transporting perishable goods is pivotal in deter

The Complete Guide To Reefer Container – Types, Specifications & Sizes

Introduction Safeguarding the freshness and quality of cold or frozen cargo is a priority in the UAE

Post a comment

You must be logged in to post a comment.