Everything You Need to Know About Shipping Containers in Ocean Freight

Shipping containers are one of the significant equipment for ocean freight. They aid the proper carriage of goods and a storage means while goods are in transit. Quality shipping containers will help minimize the occurrence of damaged cargo since the goods will be held in place in the container.

With the importance of shipping containers not being negligible, we should have a comprehensive overview of shipping containers to give you all useful information for better ocean freight experiences. So, let’s dive into this post.

Types of Shipping Containers

If you take a look at vessels on the sea, you’ll find them carrying goods of different kinds, natures, sizes, weights, etc. Of course, as there are several producing industries, there are multiple kinds of goods; hence, the need for different container types to meet these needs. Here are some of the standard containers that are used for shipping:

Standard Dry Containers

Standard dry containers are the most general type as they have more usage than any other containers. You’ll need a standard dry container to store and ship any form of dry goods. Examples include packaged goods, vehicles, machinery and parts, textiles, electronics, etc. Provided these goods are void of moisture, then the standard dry container is the ideal choice.

Refrigerated Containers

Standard dry containers are the most general type as they have more usage than any other containers. You’ll need a standard dry container to store and ship any form of dry goods. Examples include packaged goods, vehicles, machinery and parts, textiles, electronics, etc. Provided these goods are void of moisture, then the standard dry container is the ideal choice.

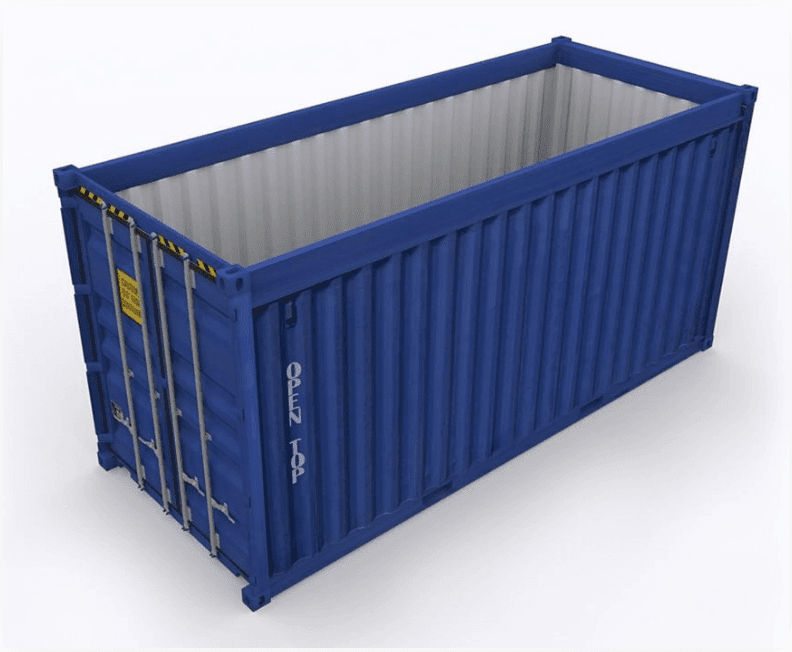

Open Top Containers

One of the main reasons for using shipping containers is to store and preserve cargo while in transit. So, in the case of goods that needs to be stored at a particular temperature during transit, refrigerated containers will come in handy. These containers are ideal for perishable goods like vegetables and fruits, and high-profile goods like chemicals and pharmaceuticals.

Flat Rack Containers

As the name suggests, it’s a container with an opening at the top. These open tops are not necessarily permanent as they could be convertibles or removable roof bows. When you need to ship bulky cargo with heights more than that of the basic container, you’ll need to resort to an open-top container. They are ideal for goods such as bulky equipment, heavy machinery, etc.

Tank Containers

These are pretty similar to the open-top containers, but in this case, it’s the sides of the containers that are removable or adjustable. You can collapse the sides of a flat rack container to allow oversized cargo to fit in. It’s yet another useful container for the family of bulky goods. Examples are large woods such as timber, heavy-duty vehicles, engineering pipes, machinery, etc. Since both sides of the container are collapsible, you can easily load and offload cargo.

This kind of container comes with tanks and is solely for the shipping of gaseous or liquid goods. Such goods include crude oil, gas, chemicals, and food-grade liquids. They are highly sophisticated with no leaks to ensure secure and safe transportation.

Specialized Containers

These are special containers for special goods. For example, insulated containers will suffice for goods that don’t need to conduct external temperature such as blood, vaccines, organs, etc. Another example is ventilated container for goods needing airflow such as furniture, fabrics, etc.

Container Dimensions and Capacity

Shipping containers come in different sizes which are determined by their dimensions. This feature also helps in determining the load capacity of each container. The common shipping container sizes are 20ft, 40ft, and 40ft High Cubes.

Understanding Container Dimensions – Length, Width, and Height

Stating the container sizes alone gives a surface view of the subject matter of dimensions. A proper lookout will result in explaining the actual meaning and details of each container size, which is provided below:

Size | Length | Width | Height |

20-foot container | 20 feet | 8 feet | 8 feet 6 inches |

40-foot container | 40 feet | 8 feet | 8 feet 6 inches |

40-foot-high cube container | 40 feet | 8 feet | 9 feet 6 inches |

Payload Capacity and Maximum Weight Limits of Shipping Containers

Here is a breakdown of the payload capacity and maximum weight according to container container.com

Size | Payload | Maximum Weight |

20- foot container | 28430kg or 62,677lbs | 30,480 kg or 67,200 lbs |

40-foot container | 26,730kg or 58,929lbs | 30,480 kg or 67,200 lbs |

40-foot-high cube container | 26,590kg or 58,620 lbs | 30,480 kg or 67,200 lbs |

Container Construction and Features

Shipping containers are able to perform their duties by virtue of how they were built or constructed. From its root materials, the containers have several features that make them suitable for carriage, storage, and transportation of goods.

Materials Used in Container Construction

Shipping containers are tough due to the durability of their primary component materials. Let’s dig deeper and have a clear picture of these materials

- Steel: This is a tough metal that accounts for the strength, resistance, and durability of the shipping container.

- Aluminum: Aluminum is another impressive metal with high resistance to corrosion. You will typically see engineers use aluminum for the door and window frames of the container

- Paints/Coating: This gives the container a good look. However, it goes further to protect the steel from rust, hence improving the lifespan.

- Wood: This is largely used for the container floor. It is on the base of the hardwood that one places cargo on.

- Composite Panel: This is used for the interior of the container in the case where partitions are needed.

- Rubber Seals and Gaskets: As apparent from their name, they seal up small spaces in the panels to prevent the entry of unwanted elements such as water, or dust.

Features of Shipping Container for Ocean Freight

With a good view of its construction materials, let’s go further to explore the features or characteristics that the shipping container exhibits.

Structural Integrity and Weather Resistance

Structural integrity is a must-have for every shipping container as they will be on the sea where they will be exposed to turbulence and harsh weather conditions. The containers are built with strong materials, like steel to ensure high strength and toughness. Every part of the container is considered including the walls and corners.

Furthermore, the shipping containers are also made to be water-tight using rubber seals and gaskets due to unpredictable weather conditions on the sea.

Flooring, Doors, and Locking Mechanism

The shipping container isn’t only about the steel wall or body, as the floor, doors, and locks are vital aspects too. The floors are usually made of hardwood while the doors and their frames are made of aluminum. Whereas, the lock system can be padlocks or electronic seals.

Ventilation and Temperature Control in Specialized Containers

Ventilation in special containers is a real deal and it is done in the following ways;

- Making small vents at the top and bottom of the container.

- The use of mechanical ventilation such as fans to blow and circulate air within the container.

- The use of a dehumidifier to control the humidity level inside the container.

In the case of goods that need a specific temperature range, different methods have been applied over time.

- The use of insulation to reduce the external temperature. Insulation materials include reflective coatings, fiberglass, and foam panels.

- For perishable and other relevant goods, a refrigerating system or unit is installed in the container.

- Heating systems can also be installed in the container for goods that do not need low temperatures such as books, dry food products, fabrics, etc.

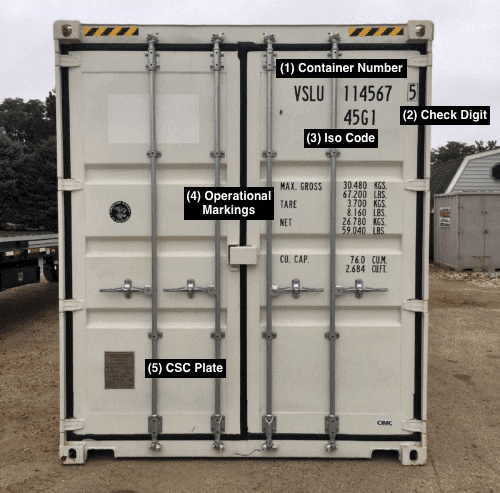

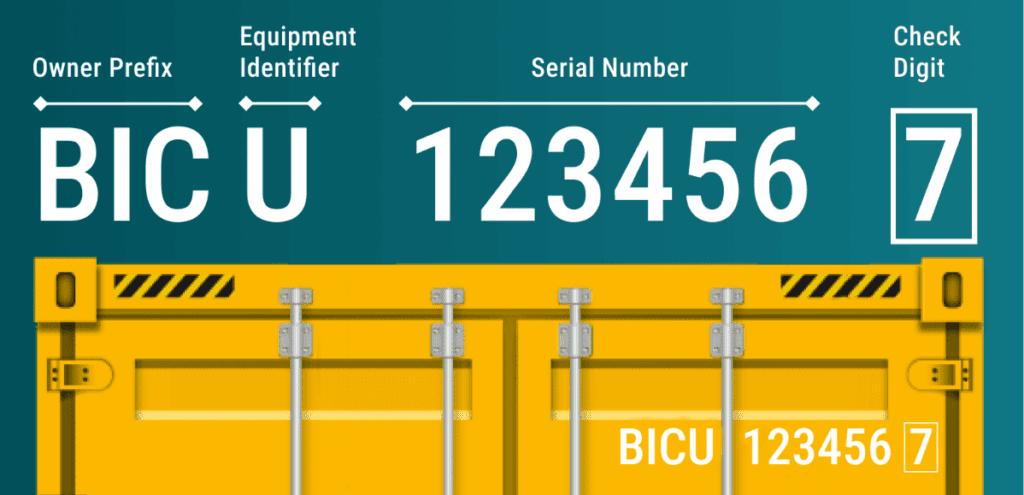

Marks and Numbers and their Meaning on Shipping Containers

It’s a norm in the industry to have marks and numbers on a shipping container. This is a means of identification and a tracking code for each container. See the image below

Container Number

Now the images reveal it all. The first three letters show the owner prefix, then the fourth letter is the equipment identifier. The first six numbers represent the serial number and the last number is the check digit.

ISO Code

This indicates the container type and dimensions. For example, an ISO code of “20G1” – the “20” show that the container is a 20-foot container. Then the “G1” is the code for general-purpose containers. Other codes include

- DC – dry container

- SC – standard container

- RC- reef container

Operational Marking

The operational markings are found below the ISO code. These markings show the maximum payload, the maximum cargo volume, and the maximum gross and tare mass.

CSC Plate

You’ll find the CSC plate at the bottom left of the container’s door. The CSC, which means Container Safety Convention Plate shows the container’s compliance with international shipping regulations.

Container Loading and Stowage

It’s understood that there are containers of different sizes and capacities. However, the placement of goods inside the container is very vital. How the goods are arranged can affect safety, stability, space efficiency, and unloading ease. So, it’s important to arrange cargo properly in the container. Let’s see some defining details.

Proper Packing and Securing of Cargo Inside the Container

Follow these guidelines to properly secure and pack the cargo inside the container:

- Choose the ideal packaging materials that suit the goods. You should put into consideration the size, fragility, and weight of the cargo. As a result, you will be able to decipher if you are to use boxes, crates, or pallets.

- Restrain each cargo for security. You can restrain with the use of ropes, belts, or straps. This will prevent cargo movement while in transit.

- Use metal or wooden braces to keep cargo in place.

- Pad fragile items to prevent impacts.

Maximizing Container Space and Weight Distribution

Here are some tips to evenly distribute weight and maximize space inside the container:

- Do not place heavy cargo all in one place, but place them in different sections of the container and at the bottom.

- Use packaging material or containers of uniform sizes.

- Pallets are a good choice for numerous cargoes as they can help maximize the space.

Consideration for Hazardous and Perishable Goods

- Pack perishable goods in appropriate containers or packages. This will involve considering the humidity, temperature, and ventilation.

- For hazardous goods, avoid placing them with incompatible goods that will cause a reaction. Learn and follow segregation rules.

- Ensure proper labeling to avoid mix-ups.

Best Practices for Safe Container Loading

- Ensure that all you do comply with the relevant regulations on loading.

- Ensure appropriate packaging and labeling.

- Take extra care and measures for fragile, hazardous, and specialized goods. This includes following specific rules for hazardous goods, including the use of cushions for fragile goods, etc.

- Evenly distribute cargo weight across the container.

- Inspect cargo before loading to identify damages or potential threats.

- Keep accurate records of loaded cargo.

Container Handling and Transportation

Several dynamics come to play in handling and transporting cargo with the use of containers. It involves loading and unloading techniques, container visibility while in transit, and the applicable safety rules. So, let’s treat each as a separate entity.

Loading and Unloading Containers at Ports and Terminals

This cuts across activities that facilitate the movement of containers within the ports or terminals to make them ready for departure. Let’s get right into it.

- Arrival of cargo inside the container at the port. If it’s a ship, it has to dock and wait for the unloading crane.

- Specialized cranes unload containers from the ship. In the case the container came in via another means, the crane will still pick up the container as it should.

- If containers are unloaded from the ship, they are transferred to the container yard with the use of rubber-tired gantry cranes.

- If the containers are meant for further transportation, then they are loaded onto trucks.

- Containers can be loaded onto outbound ships with the use of cranes.

Intermodal Transportation

Not all shopping journey is straightforward. Sometimes there is a need to employ different modes of transportation. This can involve containers arriving via ships at the ports, then they are unloaded into trucks and moved to rail cargo stations. These containers are further transported by train to the destination. That’s an intermodal transportation system.

Container Tracking and Visibility During Transit

With these, a business can monitor and know the locations of their containers while in transit. You can tell the location of your container at every given time with efficient tracking and visibility systems. The technology applied for this purpose includes:

- Radio Frequency Identification Tags: They are placed on containers and connected to a cloud database where signals of container location are reported in real-time.

- Electronic Data Interchange System: This connects every player in the chain and they share data and information on the container’s location.

- Global Positioning System: This is the most popular tracking system as the GPS tracker is placed on the container and this reports the container location in real-time.

- Internet of Things (IoT): Sensors are placed on containers and data is transmitted via satellite communication to report the container’s location at a time.

Handling and Safety Regulations for Containerized Cargo

This involves all rules and standards regarding the safety of containerized cargo. These rules include

- Ensuring efficient door lock mechanisms for containers

- The container’s structural integrity must be top-notch and inspected

- Proper classification of hazardous goods

- Even distribution of weight inside the container

- Containers must be handled by trained personnel

Container Security and Insurance

Container Seals and Security Measures

These measures are focused on the safety of the container in transit. So, let’s see what they entail.

- Use of high-security seals to prevent tamper cases. These seals are made of tough materials making them uneasy to break.

- Electronic seals add technology to the whole play. With electronic seals, there are prompts or notifications when there is tampering.

- Tracking systems like GPS and RFID help monitor containers and actions around them.

International Safety Standards and Custom Compliance

Several safety standards have been set by esteemed bodies and these rules are adopted internationally.

- Custom compliance includes the custom declaration, documentation, and security measures for containers. Proper documentation must be in place.

- The International Organization for Standardization (ISO) set the rules on coding systems to identify containers and their dimensions. The container must be tested and declared fit before use.

- International Convention for Safe Containers stands on the top-notch structural integrity for containers.

Container Inspection and Quality Control

Before loading onto a container, it must be inspected to see if it meets the quality standards of the industry. The inspection can be carried out by specialized inspection agencies, port authorities, customs authorities, etc.

The inspection includes

- Seal integrity inspection to check if the seal is efficient.

- Container weight inspection to ensure a container doesn’t carry cargo beyond the weight limit.

- Physical inspection to check for damages, leaks, and other physical issues.

Importance of Cargo Insurance for Container Shipment

Yes, insurance also comes to play regarding shipping containers. Insurance will help in the following ways.

- Risk management to reduce the financial impact of the cargo owner in the case of situations that results in the loss of cargo.

- Limitation of liability for shipping lines in the case of accidents and losses.

- Insurance boosts a brand’s competitive advantage as it gives customers the confidence to do business.

How Al Sharqi Can Help ?

If you are looking for a high-flying logistics firm to handle freight, then Al Sharqi is your best choice. With several years of experience in the supply chain and logistics industry, we offer top-quality services and freight solutions.

You need not worry about shipping containers as we will take them up from start to finish, ensuring your cargo is loaded onto the best containers and shipped to its destination in good time.

We offer;

- End-to-end visibility and tracking with an updated technology

- Full communication while your cargo is in transit

- Freight forwarding service at the best prices

- A seamless overall shipping experience

Contact Al Sharqi for more information

Conclusion

Shipping containers play a vital role in the transportation of goods. We have seen the different types of containers and their dimensions. We went further to discuss the effective ways of loading cargo onto the container and touched on the importance of container insurance. In all, you now have useful information to get your ocean freight needs resolved.

Frequently Asked Question's

The “height” is the clear difference between a standard dry container and a high cube container. High-cube containers have an increased height compared to their dry counterpart.

It all starts with identifying and measuring the dimensions, weight, and volume of your cargo. Compare the dimensions and weight with the containers available in the industry. You can get the volume of your cargo by multiplying the width, length, and height and then you can compare that with the volume the containers can accommodate.

No, you must load hazardous materials in compliance with regulations and guidelines. The International Maritime Organization (IMO) specifies strict and special packages for hazardous materials.

The key consideration is the cargo type. The cargo type determines the appropriate container. If your cargo requires special temperature needs, then you will need to use a refrigerated container.

Yes, there are regulations and restrictions on containerized cargo. The regulations cover weight limits, handling of hazardous cargo, security, and safety measures

Our customer service team is happy to assist you with planing your next booking.

Related Articles

Al Sharqi Shipping and Logistics Wins Maersk Most Valuable Partner 2023 Award

Dubai, UAE – May 24, 2024 – Al Sharqi Shipping is proud to announce that it has been awarded the

Sustainability Milestone: Al Sharqi Shipping Receives 2023 Maersk ECO Delivery Certificate158

Al Sharqi named as the Maersk Line UAE Most Valuable Partner 2022 Dubai, UAE – Al Sharqi Shipping

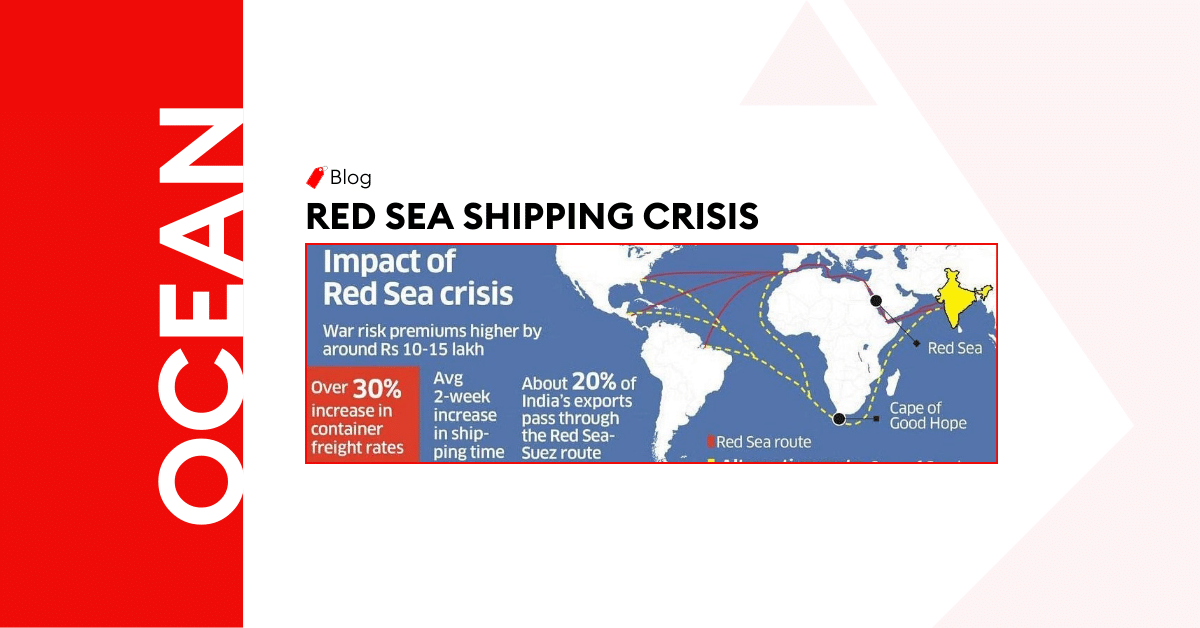

Strategic Shifts in Maritime Trade: Responding to the Red Sea Shipping Crisis

The Red Sea, a critical maritime artery connecting Europe, Asia and North America but recently it ha

Post a comment

You must be logged in to post a comment.