A Complete Guide To Insulated Shipping Container

Introduction

In global trade, where goods traverse vast distances, efficient logistics is a prominent feature of successful businesses. With the UAE’s diverse climate and the need to preserve the integrity of perishable goods during transit, insulated cargo containers are a great asset. These unique containers improve supply chain efficiency and customer satisfaction. Let’s examine the further details, including what are the inside dimensions of a shipping container, its benefits, and more.

What is an Insulated Shipping Container?

Definition and Purpose of Insulated Shipping Container

An insulated shipping container is a specialized container designed to maintain a controlled internal temperature, protecting goods from extreme environmental conditions during transportation. So, it preserves the integrity of perishable food items, pharmaceuticals, and sensitive electronics.

Differentiating Insulated Shipping Container from Other Container Types

Unlike standard shipping containers, insulated storage containers have an added layer of insulation material, often polyurethane foam or similar materials, between the inner and outer walls. This layer provides thermal resistance to maintain a stable internal temperature. Also, they cater specifically to food items, pharmaceuticals, chemicals, electronics and delicate products.

Key Features and Components of Insulated Shipping Container

- A sturdy outer structure, typically made of steel or aluminum

- An insulation layer in the inner chamber

- Tightly sealed doors and rubber gaskets

The Benefits of Using an Insulated Shipping Container

The storage container insulation comes with the following benefits:

Temperature Control for Perishable Goods

By maintaining a stable internal temperature, insulated containers create an ideal environment that prevents spoilage, bacterial growth, and other forms of degradation. This climate protects sensitive items from extreme heat or cold.

Extended Shelf Life for Temperature-Sensitive Cargo

By maintaining a consistent and controlled internal temperature, thermal insulated container prevents the degradation of perishable goods during transportation. This stability effectively slows down the natural processes that lead to spoilage, ensuring that products remain fresh and viable for a longer period.

Protection from External Temperature Variations

The insulation layer acts as a thermal barrier and prevents heat transfer between the container’s interior and the external environment. Also, it minimizes the impact of external temperature fluctuations on the cargo inside.

Prevention of Condensation and Moisture Damage

The insulation layer in thermal shipping containers also acts as a vapor barrier, reducing the likelihood of temperature differences between the container’s interior and exterior, which can lead to condensation. Additionally, the tightly sealed doors and rubber gaskets create an airtight environment, minimizing the entry of external moisture.

Suitable for Shipping Pharmaceuticals and Food Products

The insulation layer maintains a stable internal environment, safeguarding temperature-sensitive drugs and perishable food items from extreme heat or cold during transit. This prevents degradation, spoilage, and loss of efficacy in pharmaceuticals and ensures the freshness and quality of food products.

Versatility for Both Hot and Cold Cargo

For hot cargo, the insulation helps maintain a controlled and cooler internal temperature, protecting goods from heat-related damage. Similarly, for cold cargo, the insulation ensures a stable internal temperature and safeguards items from freezing temperatures.

Sustainable and Eco-Friendly Shipping Option

By effectively preserving temperature-sensitive cargo, these containers minimize the likelihood of spoilage and product damage, thus reducing the need for replacements and preventing unnecessary waste. Additionally, the insulation layer minimizes the use of external climate control systems and reduces the overall carbon footprint of shipping operations.

Get In Touch

What are the Different Dimensions of Insulated Shipping Containers?

Overview of Standard Sizes: 20ft and 40ft Insulated Shipping Container

Insulated shipping container typically comes in two variations; 20′ insulated shipping container and 40 feet container.

Internal and External Dimensions of Insulated Shipping Container

External Dimensions of 20-Foot Insulated Shipping Container

Length | Width | Height | Capacity |

20 feet long | 8 feet wide | 8.6 feet high | About 1,150 cubic feet |

Internal Dimensions of 20-Foot Insulated Shipping Container

Length | Width | Height | Capacity |

19.4 feet long | 7.7 feet wide | 7.9 feet high | About 1,150 cubic feet |

External Dimensions of 40-Foot Insulated Shipping Container

Length | Width | Height | Capacity |

40 feet long | 8 feet wide | 8.6 feet high | About 2,350 cubic feet |

Internal Dimensions of 40-Foot Insulated Shipping Container

Length | Width | Height | Capacity |

39.5 feet long | 7.7 feet wide | 7.9 feet high | About 2,350 cubic feet |

High-cube versions of these containers exist, which are 9.6 feet high instead of 8.6 feet, offering slightly increased internal height and capacity.

Load Capacity and Weight Restrictions

- 20-foot Insulated Shipping Container

- Maximum gross weight (Container + Cargo): Approximately 24,000 kg to 30,480 kg

- Payload capacity (Cargo Weight): Approximately 21,000 kg to 27,480 kg

- 40-foot Insulated Shipping Container

- Maximum gross weight (Container + Cargo): Approximately 30,480 kg to 32,500 kg

- Payload capacity (Cargo Weight): Approximately 26,480 kg to 28,500 kg

Characteristics of Insulated Shipping Containers

Unique Design Features and Construction of Insulated Shipping Containers

- Insulation layer between the inner and outer walls.

- Temperature control systems, such as air conditioning or refrigeration units.

- Moisture resistance via tightly sealed doors and rubber gaskets.

- Airtight sealing between the interior and exterior.

- Strong and durable construction from robust materials, such as steel or aluminum

Flooring and Load Securing Mechanisms

The flooring of insulated shipping containers typically incorporates marine-grade plywood or other durable materials that can withstand heavy loads and frequent handling. Load securing mechanisms help to secure the cargo inside the container during transit using lashing rings, E-tracks and D-rings, wooden battens, and dunnage bags or airbags.

Structural Strength and Durability

The materials used in constructing insulated containers are usually high-quality, corrosion-resistant and expertly welded together, creating a seamless and robust structure. Other key features are reinforced corners and corrugated walls and roofing.

The Most Common Applications of Insulated Shipping Container

Overview of Industries and Cargo Types That Utilize Insulated Shipping Containers

The food industry requires insulation for transporting perishable goods like fruits, vegetables, and dairy products. Pharmaceuticals and healthcare producers ship temperature-sensitive medications and vaccines. Also, the technology sector benefit from thermal insulated containers to ship delicate electronic components.

Examples of Specific Goods Transported Using Insulated Shipping Container

- Fruits and vegetables

- Seafood and dairy products

- Vaccines, and other temperature-sensitive medical supplies

- Chemicals and hazardous materials

- Sensitive electronics, such as semiconductors and high-tech equipment

- Other goods like flowers, chocolates, and beverages

How Al Sharqi Can Help with Insulated Shipping Container

Al Sharqi is your reliable logistics and supply chain provider that offers expert handling and transportation services for specialized cargo. We ensure the safe and secure movement of temperature-sensitive goods via our extensive network coverage across the UAE. By integrating with supply chain management solutions, Al Sharqi provides tailored solutions according to your business requirements. Contact us at Al Sharqi to get your goods to their destination in prime condition.

Conclusion

Understanding the unique design features of Insulated containers ensures the safe transportation of temperature-sensitive cargo, ranging from perishable foods to pharmaceuticals and electronics. For shipping experts, this knowledge is significant, as it helps to optimize logistics operations, enhance product quality, and reduce waste. Opt for insulated container shipping today, and unlock secure and efficient logistics.

FAQs

Our experience in the field and our global network

The insulation layer within the interior and exterior of the container acts as a thermal barrier, preventing heat transfer between the container’s interior and the external environment. Additionally, airtight sealing and moisture resistance prevent condensation or moisture buildup.

Perishable food items like fruits, vegetables, seafood, and dairy products, pharmaceuticals, vaccines, medical supplies, sensitive electronics, chemicals, and flowers.

During hot weather, insulated shipping containers create and maintain a cooler internal environment, while in freezing temperatures, the insulation retains heat within the container.

Insulated containers carry delicate cargo that require precise temperature regulation during transportation, shielding these goods from extreme weather conditions and preventing spoilage, degradation, and damage.

An insulated container features a specialized insulation layer, typically made of polyurethane foam, between its inner and outer walls. This material acts as a thermal barrier, preventing heat transfer and minimizing the impact of external temperature fluctuations.

To insulate a shipping container, follow these steps:

- Clean and Prepare: Ensure the container is clean and dry.

- Apply Insulation: Attach insulation material like foam panels or spray foam to the container’s interior walls and ceiling.

- Seal Gaps: Seal gaps with caulk or tape to prevent air leakage.

- Add Interior Finish: Install a vapor barrier and add an interior finish like plywood or drywall to complete the insulation process.

The insulated shipping container cost can vary widely depending on factors such as size, insulation type, quality, and additional features. Generally, you can expect to pay anywhere from $2,000 to $5,000 for a basic insulated shipping container. High-quality, larger containers with advanced insulation might cost more, potentially exceeding $10,000. It’s recommended to get quotes from suppliers or manufacturers to get a more accurate estimate based on your specific needs.

Related Articles

The Ultimate Guide to Dry Container {Types, Dimensions & Specifications}

Introduction In the vast ocean of international trade, about 90 percent of cargo transport relies on

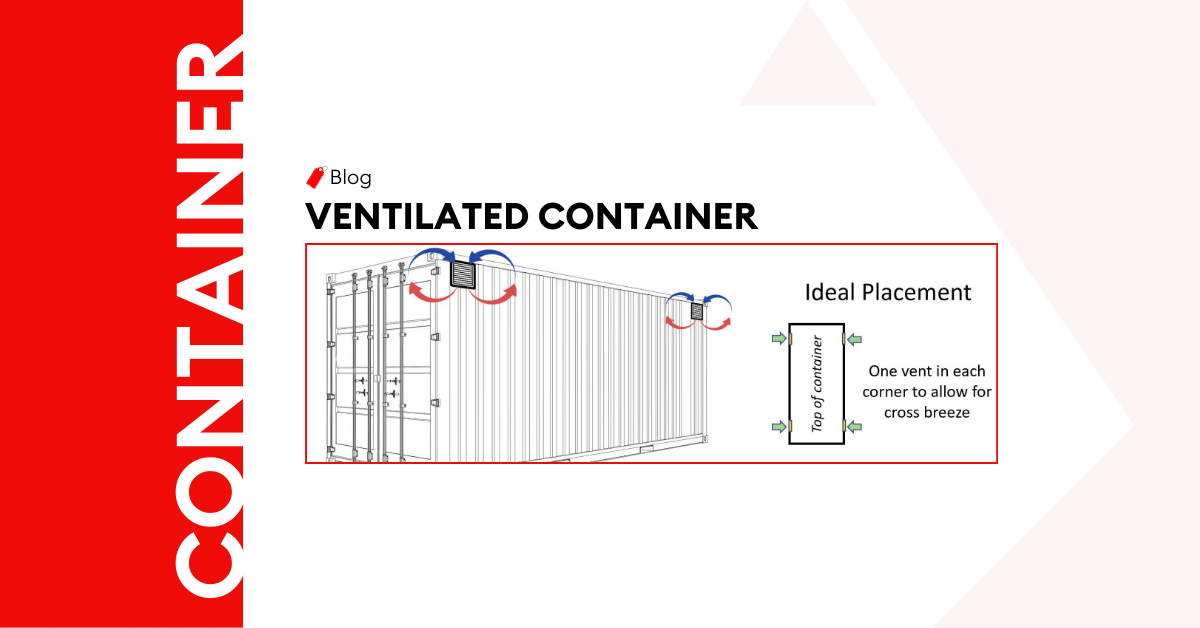

What is Ventilated Container – A Complete in Dept Guide

Introduction In the dynamic world of global trade, transporting perishable goods is pivotal in deter

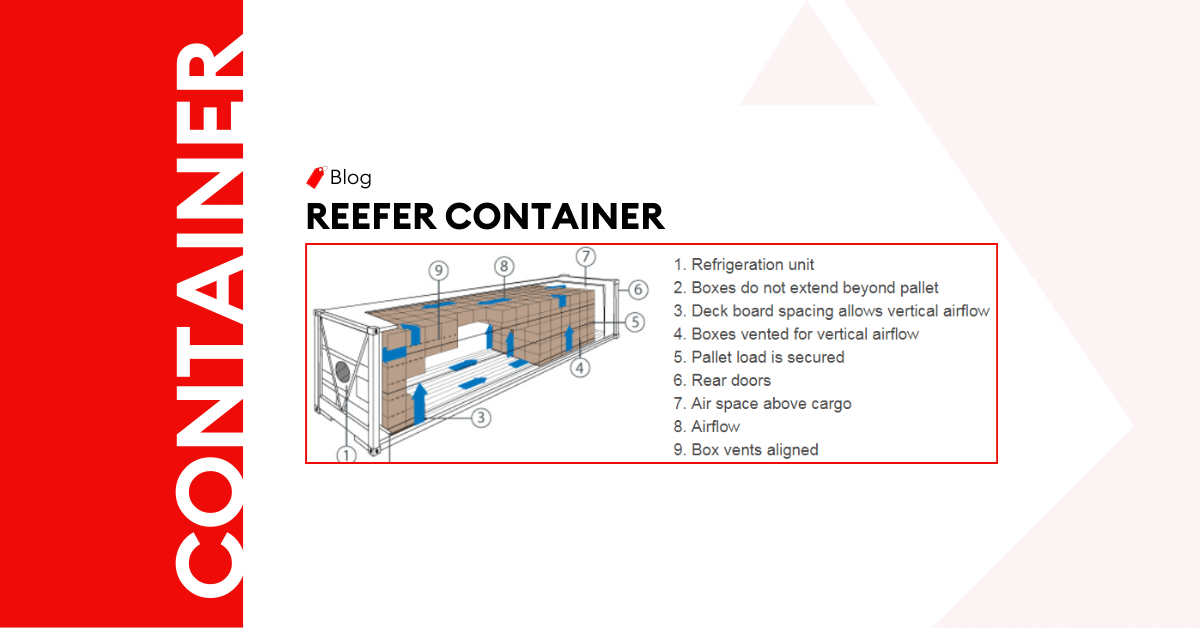

The Complete Guide To Reefer Container – Types, Specifications & Sizes

Introduction Safeguarding the freshness and quality of cold or frozen cargo is a priority in the UAE

Post a comment

You must be logged in to post a comment.