Dedicated Warehouse Space in Dubai- How Do They Work?

Warehouses are an important element of the supply chain. They can be built by an organization or acquired via rent or lease. Dedicated warehouse space is a one rented or leased to a single business or organization. This organization takes full control of the warehouse space and can implement more customized operations.

Dedicated warehouse spaces in Dubai enable businesses to meet their specific logistics needs without distractions from other organizations, like in a shared space. It helps businesses improve inventory management, storage, and order fulfillment. This will lead to streamlined supply chain operations.

Key Features and Functions of a Dedicated Warehouse Space

The features and functions of warehouse space are connected. Ideal warehouse space has features that enable the warehouse to perform its duties as a key element of the supply chain and logistics space. This section will outline these vital features and point out the activities that go on in a dedicated warehouse space.

Warehouse Infrastructure and Layout

The warehouse infrastructure starts from the basic components of the building that makes the space useful. This includes flooring, roofs, walls, and columns. They must be in perfect shape void of cracks, leakages, and other faults.

A dedicated warehouse space must have arrangements that will optimize workflow, utilize space, ensure free flow traffic, allow room for growth, and boost the overall efficiency of the warehousing system.

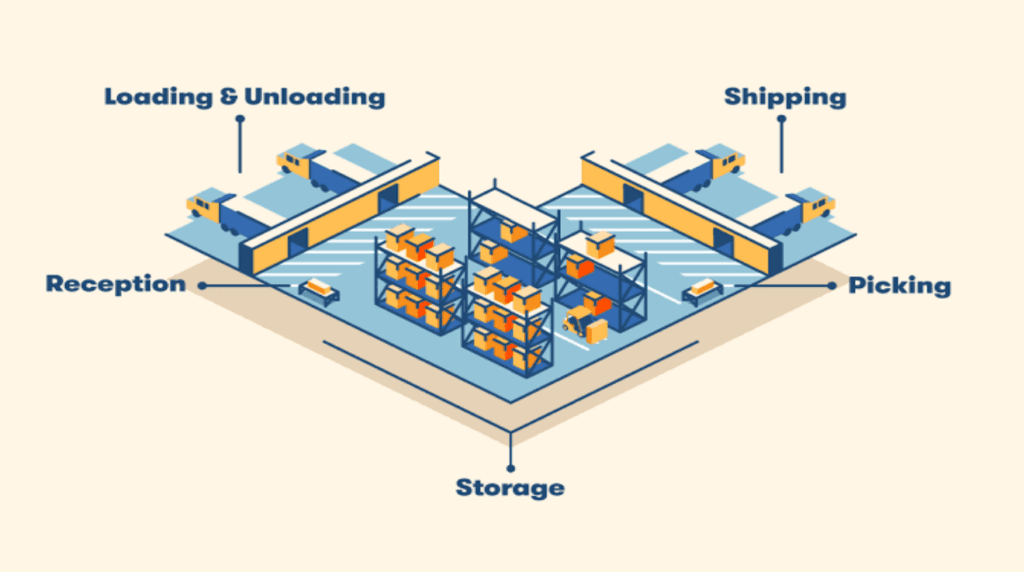

An ideal dedicated warehouse space layout will have the following

- Receiving Area: Incoming goods are unloaded in this space; hence, it should be close to the dock doors. The receiving area should have enough space for sorting before goods are stored.

- Storage Area: This is the area where goods will be stored until they are ready for shipping.

- Sorting Area: This is an area where goods are picked, packed, and ready for shipping or delivery. The sorting area should not be far from the storage area for easy movement of goods.

- Shipping Area: This is where the goods are placed after sorting. They are then loaded onto outbound vehicles.

- Efficient Pathways: The pathways must be fitted into the design to grant smooth movement of personnel, goods, and equipment from one section of the warehouse to another.

Storage Capacity and Configuration

The storage capacity of the warehouse means the available space for storage. Not all the space in the warehouse is allocated for storage since there are other vital sections of the warehouse, such as the sorting area, receiving area, etc. However, a dedicated warehouse space should have a storage capacity that suits the needs of the business. This means that businesses that handle large volumes of goods will need warehouse spaces with high storage capacity. The reverse can be the case for small-scale businesses.

Here is a quick way to determine the storage capacity of a dedicated warehouse space.

- Calculate the measurement of the entire warehouse space in square feet. Let’s say you have 200,000 sq. ft.

- Calculate the entire space not used for storage. Let’s say you have 20,000 sq. ft.

- Subtract the amount of space not used for storage from the measurement of the entire warehouse space. This will be 200,000 – 20,000 (sq. ft.), resulting in 180,000 sq. ft. So, there is 180,000 sq. ft. of usable space.

- Measure the storage space in terms of height. You can use the height of the warehouse rack as a reference. Let’s say 50ft.

- Multiply the usable space by the height measured. This will give 180,000 x50 = 9,000,000 cubic feet. This is the storage capacity of the dedicated warehouse space.

The storage configurations are patterns or systems in which inventories are stored to optimize space utilization. Here is a rundown of the common storage configurations.

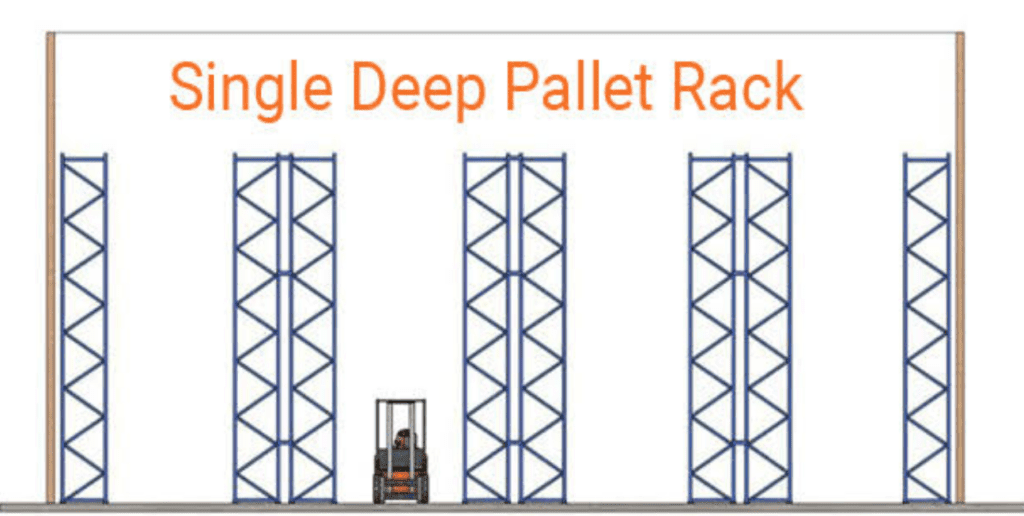

Single Deep Racking

Inventories packed in pallets are stored in a single row, which allows direct access to each pallet. This configuration is ideal when accessibility is of utmost importance.

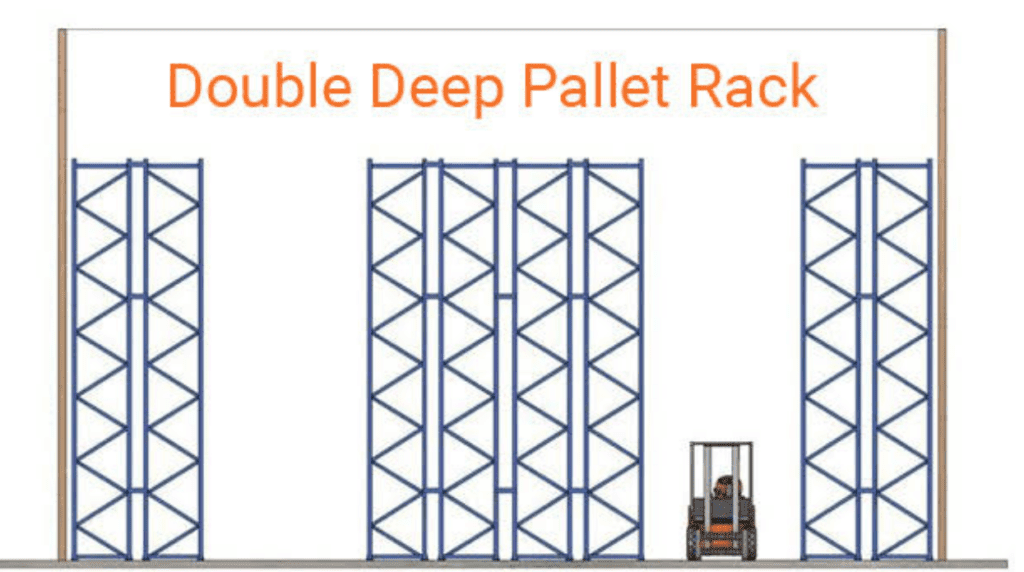

Double Deep Racking

This configuration increases storage density since a maximum of four rows of inventories can be placed back-to-back. A forklift is used to access the rear of the rack.

Push Back Racking

Push back racks consist of carts on rails on which the goods are stored. Loading a new inventory will push the other backward via the moving rail.

This configuration is used for storing inventories of irregular shapes or lengths, such as furniture, pipes, etc. Cantilevers have arms extending from vertical columns.

Mezzanine

This is an elevated platform on vertical racking systems to provide additional storage space. It is ideal for light-weight inventories.

Advanced Warehouse Management System

An advanced warehouse management system is a technological implementation that improves efficiency and workflow in the warehouse. This software is used for the following.

- Order management: It helps categorize orders for proper processes and delivery schedules. It also boosts efficiency in order processes, such as picking and sorting. Order management becomes streamlined with advanced warehouse management systems.

- Inventory management: Advanced warehouse management system helps with monitoring inventory levels. It makes it easy to track inventory movements and spot inventory for other activities. This will prevent overstocking, stockouts, and goods expiration.

Advanced warehouse management systems can also help monitor the productivity of personnel by assigning tasks and organizing every operation.

Value- added Services and Customization

Apart from storage, dedicated warehouse space offers a platform for other services as listed below.

- Quality control inspection: Inventories are checked regularly to ensure quality is preserved.

- Order fulfillment: This involves every step that prepares an inventory for delivery. You will get access to efficient fulfillment services involving picking, packing, and timely shipping.

- Inventory management: This involves monitoring and tracking inventory to prevent overstocking, or running out of stock.

- Customized reporting: Tailored reports providing detailed insights into inventory levels, order processing, and Key Performance Indicators (KPIs) to support your decision-making process.

- Cross docking: Quick transfer of goods from inbound vehicles to outbound vehicles to timely delivery and reduction of handling time.

- Reverse logistics: Comprehensive management of product returns and responsible disposal.

- E-commerce integration: Seamless integration with your e-commerce platforms for streamlined order management and synchronization.

- Labeling and packaging customization: Personalized labeling, branding, and customized packaging designs to enhance your product presentation.

- Kitting and assembly: Customized packaging and assembly services to meet your specific product bundling requirements.

Rental and Leasing Options for Dedicated Warehouse Space

Dedicated warehouse space can be rented or leased in Dubai. Each model has its characteristics and principles.

Renting and Leasing Models

Warehouse Rental Model

One can rent a dedicated warehouse space in Dubai. This model involves a short-term agreement between the facility owner and the business, which usually last for some months to a year. The rental fee varies and depends on the facility infrastructure, location, space capacity, and the facility owner.

A security deposit is sometimes paid to the facility owner. This fee is refundable as it is a cover in the case of damage to the facility or a breach of contract.

Warehouse Lease Model

This model gives dedicated warehouse space for a longer period of time. This period of time can be for several years. Payments can be made monthly, quarterly, or yearly. A security deposit can also be paid depending on the demand of the facility owner.

Long-term Vs Short-term Contracts

The renting and leasing models outrightly show that there are two forms of contract for dedicated warehouse space in Dubai. This refers to long-term and short-term contracts. Both have their advantages and benefits to a business.

Benefits of Long-term Contracts

- Planning and forecasting: Long-term contracts give the business room to plan and forecast its warehouse activities over a long period of time. This will factor in operational costs, inventory levels, storage requirements, and the overall supply chain management.

- Stability and security: It stabilize the business since there is no uncertainty and a need to search for a new space within a short period.

- Customization and infrastructure: Long-term contracts for a dedicated warehouse space give businesses a platform to control and design the space to meet its specific needs. Businesses can influence the infrastructure for unique operations.

- Scalability and growth: Since businesses can plan for years by virtue of long-term contracts, it creates a solid base for scalability and growth. There is efficient planning for increased operations and customer base.

- Cost savings: Long-term contracts offers the opportunity for discounted leasing fees. This will suffice for cost savings compared to paying consistently for different warehouses spaces with different landlord requirements.

Benefits of Short-term Contracts

- Ease for small-scale businesses: Short-term contract is ideal for small businesses and start-ups as they may not have the capacity to bear huge financial burden and cost.

- Testing new markets: Businesses that want to test new markets do not want to be stuck in a particular geographic location. Short-term contracts reduce the commitments and aids businesses switch locations as they intend to explore new markets.

- Project-Based Operations: It offers a good platform for project-based operations. This involves when businesses have a project and need a warehouse space for a small duration.

Operational Processes and Management of Dedicated Warehouse Space

This involves all activities that go on in the warehouse resulting in the proper flow, storage, and delivery of inventories.

Inbound and Outbound Operations

Inbound

- Receiving: This involves accepting incoming goods. The quantity and quality of goods are verified before they are logged into the inventory database for records.

- Sorting: Upon verification, goods are unloaded from inbound vehicles and sorted. It is based on criteria such as goods type, destination, manufacturer/supplier, delivery time, and specific storage needs like refrigerated storage.

- Storage: After sorting, goods are placed in the appropriate storage location or system until they are ready for shipment.

Outbound

- Order Processing: This kickstarts the outgoing phase as the warehouse operators need to check inventory availability and order details after an order has been placed.

- Picking: The ordered goods are picked from their storage locations. This can be manual picking or automated picking.

- Packing: The picked goods are packed with the appropriate packaging materials. After packing, the goods are labeled and ready for shipment.

- Loading and Shipping: Goods are loaded onto outbound vehicles and shipped out of the warehouse to the stated destination.

Inventory Management and Control

Inventory management involves organizing the inflow and outflow of goods, monitoring stock levels, and ensuring the availability of products as they are needed. Inventory management includes activities such as inventory planning, procurement, inventory tracking, and control.

Some best practices for inventory management include:

- Implementation of accurate and detailed inspection upon receiving goods into the warehouse.

- Implementation of technological-based tracking systems, such as the Warehouse Management System.

- There should be regular cycle counts and audits to double check records to minimize inaccuracies.

- Implementation of clear and consistent product identification systems such as RFID tags, barcodes, etc.

- Regular inspection and analysis on inventory management performance and procedures to identify areas that needs improvement.

Order Fulfillment and Distribution

Order fulfillment and distribution involve all activities that make a product ready for shipping or delivery after an order has been made. Here is a rundown of the processes involved in order fulfillment.

- Receive: Receiving orders from customers.

- Order processing: Order details are checked for accuracy and availability of the product.

- Order picking: Orders are picked annually or automatically from their storage locations.

- Quality check: The picked products are further assessed to ensure accuracy and quality.

- Order packing: Products that passes the quality check are packed with packaging materials.

- Documentation and labeling: The packaged orders are labeled and necessary invoices are generated.

- Shipment and tracking: The packaged orders are loaded onto outbound vehicles or carrier. The shipment tracking ID is sent to customers and other players for real-time tracking.

Safety and Security Measures

There is a need to implement safety measures in a dedicated warehouse space. It is vital since it offers immense benefits to the business. Well-implemented safety measures will ensure the following:

- Boost employee safety by reducing the risk of accidents, injuries, etc.

- Prevent inventory loss, which can happen through theft, damage, accidents, etc.

- Boost customer trust and satisfaction, which in turn ensures business continuity.

- Protects the brand’s reputation as issues of security concern will not speak well about the brand.

Some safety measures that can be implemented in a dedicated warehouse space include:

- Training personnel or employees on safety. This will include how to handle equipment and appropriate responses to different situations in the warehouse.

- Proper layout of the warehouse with clear signage and markings to indicate safety precautions.

- Implementation of security personnel and surveillance systems to monitor activities in the warehouse.

- Implementation of fire safety measures such as fire alarms, emergency exits, fire suppression systems, etc.

Manpower and Scheduling

The manpower and scheduling must be at an efficient level for improved productivity and operations in the warehouse. The manpower consists of employees playing different roles in the warehouse and appropriate scheduling ensures that no task is left out but handled in a timely manner. Efficient manpower and scheduling will lead to:

- Improved warehouse operations.

- Elimination of overburdening work schedules that will take a toll on employees. This will boost employees’ morale, safety, and health.

- Improved customer service and satisfaction.

Value Proposition of Dedicated Warehouse Space in Dubai

This section will communicate the value which a dedicated warehouse space in Dubai will offer to your business.

Strategic Location and Connectivity

Dubai itself is a commercial city with state-of-the-art connectivity and transport networks. Dedicated warehouse space in Dubai offers your business access to good shipping points to Asia, Europe, and Africa.

Aside from the road infrastructures, here are other necessary fractures available for the movement and delivery of goods locally and internationally.

- Outstanding rail network that connects Dubai to other Emirates of the UAE and neighboring countries.

- Advanced Jebel Ali seaport.

- The prestigious Al Maktoum International Airport.

All these outlets will ease the transportation of goods and access to different markets.

Scalability and Flexibility

Dedicated warehouse spaces in Dubai can be obtained via rental or lease. This means that you can get these warehouses for both the long-term and the short-term. Each dynamics suits different needs which provides flexibility.

For example;

- Short-term rental can help small businesses and project/contract-based operations.

- A long-term lease will allow efficient planning for upscaling activities.

- Short-term rental can help when testing new markets.

In all, dedicated warehouse spaces in Dubai takes a dynamic structure, providing solutions for different business needs.

Focus on Core Competencies

A dedicated warehouse space eliminates distractions that are commonly experienced in shared warehouses. There is much more control and competence. Businesses have the leeway to deal with their preferred product line, distribute tasks, and pay more attention to their core competencies.

How Al Sharqi Can Help

It is one thing to acquire a dedicated warehouse space and another to set it up for efficient operations. Setting it all up can be quite challenging and this is where Al Sharqi comes to play. You get the infrastructure and we will help run the warehouse efficiently.

We will bring top-expertise to life as we offer:

- Efficient manpower

- Streamlined standard operation processes

- Software implementation to all levels of warehouse operations.

We can get your warehouse up and running. Contact Us

Conclusion

Dedicated warehouse space provides more control over inventory management, and storage, and improved efficiency of warehouse operations. This warehouse space can be gotten as a short-term rental or long-term lease. Whatever the model, the dedicated offers great value such as scalability, connectivity, and access to markets. Dedicated warehouse space in Dubai proves to be a strategic solution for efficient supply chain operations within the region. Hence businesses are encouraged to implement as appropriate.

Frequently Asked Questions

This is a warehouse space that is acquired by lease or rent for utilization by a single organization. The organization has full control of the entire facility.

It helps to improve supply chain efficiency for businesses in Dubai. This will include streamlining the process of storage, inventory management, and order fulfillment.

- Dedicated warehouse space can be acquired by short-term rental or long-term lease. This contract mode is discussed and agreed between the facility owner and the business. Then necessary payment and documentation are made.

A long-term contract means that the facility owner is leasing the warehouse space to a business for a long period of time ranging from several years to a decade. Then a short-term contract means the facility owner is renting out the warehouse space for a short time, which could be a few months.

- The current demand for warehouse space will influence cost. High demand may lead to increased costs.

- Location matters a lot. Warehouse spaces in a busy location having excellent transport network and connectivity tends to attract high cost.

- The size of the warehouse space will influence the cost. Larger spaces will attract more cost than smaller spaces.

- The lease time or duration will affect the cost. Long term leases may attract discounts.

- The infrastructure of the warehouse space is a cost determiner. Modern infrastructure will attract more cost.

Our customer service team is happy to assist you with planing your next booking.

Related Articles

Optimize Warehousing, Fulfillment and Shipping Cost

In today’s fast-paced business environment, efficient distribution and shipping play a crucial

Frozen and Chilled Storage Warehouse in Dubai

Dubai’s hot climate means efficient storage is a prominent concern for manufacturers and selle

Keeping Your Food Safe with Food Grade Warehouse in Dubai

Currently, the United Arab Emirates (UAE) relies on other countries for the bulk of its food supplie

Post a comment

You must be logged in to post a comment.